Temperature Range Temperature Rating - IHI PCB connectors

Q: What is the Temperature Range or temperature rating of IHI Tin plated aluminum PCB connector lugs?

A: There are two areas to discuss, the connector itself and the entire device in which the connectors is used.

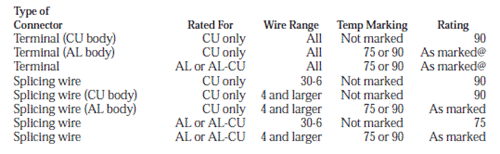

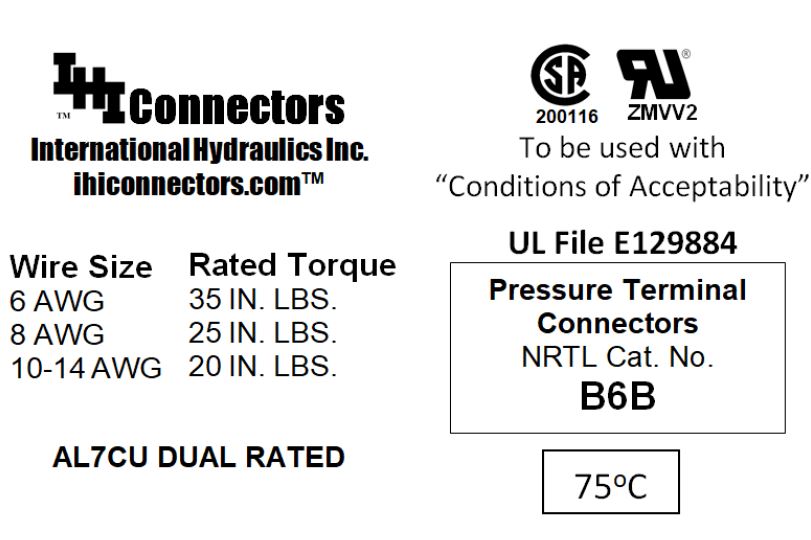

1. UL and CSA under UL486A-B and C22.2 No.65 standards define the MAXIMUM OPERATING temperature of the connector using the 75C and 90C temperature rating codes 7 and 9. (see Agency labels below for examples of 75C and 90c connectors).

2. Derating of maximum current using the largest rated wire is done using NEC derating tables (below) which takes operating temperatures higher than 30C and lowers the current, to allow for less I^2R watts of heat generation to offset the higher ambient temperature. At some high ambient temperature, the useful current rating of the wire and connectors, and certainly even more so the PCB copper foil traces, is too limited unless forced cooling is used.

All of the test data for UL and CSA tested connectors is with “free air” flow, not forced air. User of fans, liquid cooling and large heat sinks change the temperature equations dramatically which is why the engineering of the whole device is in the hands of the OEM designer not the maker of the connectors.

3. Testing of connectors by UL and CSA and other accredited test labs includes a 500 cycle, over current, accelerated aging stress test on these connectors. There is a disqualification of the test if the temperature rises over 125C above ambient test temperature.

125C is not a recommended maximum operating temperature but a guide for perspective. Generally, a connector that rises in temperature by 125C in free air would often fail the 500 cycles test, somewhere between 100C-125C rise over ambient.

4. Low temperature ambient temperatures. Historically the testing standard is based on maximum temperatures since current creates heat and heat is the ultimate barrier to larger current flow. There is no lower temperature suggested in the UL486A-B connector standard except that connectors can be uprated for cooler ambient temperatures in place of down rated (see NEC tables).

Recently UL and CSA have added low temperature testing for connectors with polymeric insulation since some plastics do suffer from cracking at low temperatures and often the plastic needs to be crimped or bent or otherwise strained in installation.

For polymeric components of a connector the test temperature picked by UL /CSA is -10C.

Again, this is not a lower limit on operating temperature but more a point on the scale below which an installation technician would be concerned about cracking plastic components of metal and plastic connector such as crimp lugs.

IHI PCB connectors are uninsulated and so do not contain polymeric materials in their structure.

5. Only the OEM designer can both design and test the final assembly for a known ambient temperature performance.

Outside specialist labs that perform this kind of whole product testing are able to provide pass fail to industry recognized tests.

6. As an example, from an OEM customer’s published literature with several IHI PCB connectors on a complete “tropicalized” power controller product that still performs after 20 years of sales in the global markets:

Environmental:

Ambient: -40C to +60C

Storage: -40C to +80C

Humidity: 100% (No condensation)

High Temp shutdown:

70C disconnect line power source

80C disconnect load (battery power)

60C reconnect load (battery power)

50C Reconnect Line power source

This product was subjected to significant Third Party stress and environmental testing to support the offered temperature specs and has significant internal temperature monitoring protections to avoid self-destruction.

Notably above you see the 70C maximum temperature line power shutdown and 80C battery power shutdown.

Rather closely aligned to the 75C max nominal rating of the PCB connector.

IHI can make no projections of the connectors temperatures in use which is solely the role of the OEM to determine. |

75C Rating

|

90C Rating

|

Ampacities of Insulated Conductors From NEC Table 310.16 (2020 edition)

Not More than Three Conductors in Raceway, Cable or Earth (Directly Buried)

(Based on Ambient Temperature of 30° C, 86° F)

The previous table version can be seen here. |

| Print this Page |

| Size |

Copper Conductors |

Aluminum Conductors

Copper-Clad Conductors |

| |

60° C

(140° F) |

75° C

(167° F) |

90° C

(194° F) |

|

|

60° C

(140° F) |

75° C

(167° F) |

90° C

(194° F) |

|

AWG

Kcmil |

Types |

Types |

Types |

Types |

Types |

Types |

|

|

|

|

|

|

|

TW |

RHW |

TBS, SA, SIS, |

TW |

RHW |

TBS |

|

|

|

|

|

|

|

|

UF |

THHW |

FEP, FEPB, MI, |

UF |

THHW |

SA, SIS |

|

|

|

|

|

|

|

|

|

THW |

PFA, RHH, |

|

THW |

THHN, THHW |

|

|

|

|

|

|

|

|

|

THWN |

RHW-2, THHN, |

|

THWN |

THW-2 |

|

|

|

|

|

|

|

|

|

XHHW |

THHW, THW-2, |

|

XHHW |

THHW-2, RHH, |

|

|

|

|

|

|

|

|

|

XHWN |

THWN-2, |

|

XHWN |

RHW-2, USE-2, |

|

|

USE |

USE-2, XHH, |

|

USE |

XHH, XHHW, |

|

|

ZW |

XHHW, XHHW-2, |

|

|

XHHW-2, XHWN |

|

|

|

XHWN, XHWN-2, |

|

|

XHH, XHHW |

|

|

|

XHHN, Z, ZW-2 |

|

|

XHWN-2, XHHN |

| |

|

|

|

|

|

|

| 18 * |

- |

- |

14 |

- |

- |

- |

| 16 * |

- |

- |

18 |

- |

- |

- |

| 14 * |

15 |

20 |

25 |

- |

- |

- |

| 12 * |

20 |

25 |

30 |

15 |

20 |

25 |

| 10 * |

30 |

35 |

40 |

25 |

30 |

35 |

| 8 |

40 |

50 |

55 |

35 |

40 |

45 |

| 6 |

55 |

65 |

75 |

40 |

50 |

55 |

| 4 |

70 |

85 |

95 |

55 |

65 |

75 |

| 3 |

85 |

100 |

115 |

65 |

75 |

85 |

| 2 |

95 |

115 |

130 |

75 |

90 |

100 |

| 1 |

110 |

130 |

145 |

85 |

100 |

115 |

| 1/0 |

125 |

150 |

170 |

100 |

120 |

135 |

| 2/0 |

145 |

175 |

195 |

115 |

135 |

150 |

| 3/0 |

165 |

200 |

225 |

130 |

155 |

175 |

| 4/0 |

195 |

230 |

260 |

150 |

180 |

205 |

| 250 |

215 |

255 |

290 |

170 |

205 |

230 |

| 300 |

240 |

285 |

320 |

195 |

230 |

260 |

| 350 |

260 |

310 |

350 |

210 |

250 |

280 |

| 400 |

280 |

335 |

380 |

225 |

270 |

305 |

| 500 |

320 |

380 |

430 |

260 |

310 |

350 |

| 600 |

350 |

420 |

475 |

285 |

340 |

385 |

| 700 |

385 |

460 |

520 |

315 |

375 |

425 |

| 750 |

400 |

475 |

535 |

320 |

385 |

435 |

| 800 |

410 |

490 |

555 |

330 |

395 |

445 |

| 900 |

435 |

520 |

585 |

355 |

425 |

480 |

| 1000 |

455 |

545 |

615 |

375 |

445 |

500 |

| 1250 |

495 |

590 |

665 |

405 |

485 |

545 |

| 1500 |

525 |

625 |

705 |

435 |

520 |

585 |

| 1750 |

545 |

650 |

735 |

455 |

545 |

615 |

| 2000 |

555 |

665 |

750 |

470 |

560 |

630 |

|

Notes:

1. Section 310.15(B) shall be referenced for ampacity correction factors where the ambient temperature is other than 30 C (86 F).

2. Section 310.15(C)(1) shall be referenced for more than three current-carrying conductors.

3. Section 310.16 shall be referenced for conditions of use.

*Section 240.4(D) shall be referenced for conductor overcurrent protection limitations, except as modified elsewhere in the Code.

|

Correction Factors for Ambient Temperature From NEC Table 310.15(B)(1) Over 30° C, 86° F |

| For Ambient Temperatures Over 30° C, 86° F, multiply the ampacities shown above by the appropriate factor show below: |

| Ambient Temperature |

Copper Conductors |

Aluminum Conductors

Copper-Clad Conductors |

21-25 C,

79-77 F |

|

1.08 |

1.05 |

1.04 |

|

|

1.08 |

1.05 |

1.04 |

|

26-30 C,

78-86 F |

1 |

1 |

1 |

1 |

1 |

1 |

31-35 C,

87-95 F |

0.91 |

0.94 |

0.96 |

0.91 |

0.94 |

0.96 |

36-40 C,

96-104 F |

0.82 |

0.88 |

0.91 |

0.82 |

0.88 |

0.91 |

41-45 C,

105-113 F |

0.71 |

0.82 |

0.87 |

0.71 |

0.82 |

0.87 |

46-50 C,

114-122 F |

0.58 |

0.75 |

0.82 |

0.58 |

0.75 |

0.82 |

51-55 C,

123-131 F |

0.41 |

0.67 |

0.76 |

0.41 |

0.67 |

0.76 |

56-60 C,

132-140 F |

- |

0.58 |

0.71 |

- |

0.58 |

0.71 |

61-65 C,

141-149 F |

- |

0.47 |

0.65 |

- |

0.47 |

0.65 |

66-70 C,

150-158 F |

- |

0.33 |

0.58 |

- |

0.33 |

0.58 |

71-75 C,

159-167 F |

- |

- |

0.50 |

- |

- |

0.50 |

| 76-80 C, 168-176 F |

- |

- |

0.41 |

- |

- |

0.41 |

81-85 C,

177-185 F |

- |

- |

0.29 |

- |

- |

0.29 |

|

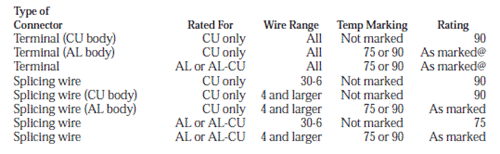

UL White Book Notes on Ampacity Level Rating for ZMVV UL486A-B connectors

Ampacity level rating:

A. Equipment use — Equipment wiring requirements may restrict the sizing, ampacity and temperature ratings of connected conductors. Equipment requirements may limit 90°C or higher-rated conductors to 60 or 75°C ampacity in accordance with Electrical Equipment for Use in Ordinary Locations (AALZ).

B. General use — Connectors rated 75°C are intended for use at ampacities not greater than those for 75°C-rated conductors, and connectors rated 90°C are for use at ampacities not greater than those for 90°Crated conductors. Connectors may be marked with ‘‘75C’’ or ‘‘90C’’ to represent these levels. Alternatively, these rating levels may be represented by a 7 or 9 associated with the marking ‘‘CU,’’ ‘‘AL’’ or ‘‘ALCU,’’ e.g., ‘‘AL9,’’ ‘‘AL9CU,’’ ‘‘AL7CU,’’ ‘‘CU7,’’ ‘‘CU9.’’ Connectors not marked with an ampacity number 7 or 9 have an assumed level per the following table. Use of higher-temperature-rated conductors is not prohibited, provided the ampacity levels continue to be based on the 75 or 90°C ratings.